JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

STRAIGHT ROLLER TRACK TABLES - LTSRT RANGE

Straight Roller Track Tables

Product Overview

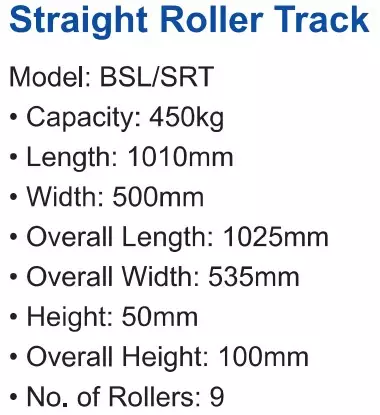

The Straight Roller Track Tables are designed to streamline loading and unloading operations, making material handling more efficient. Equipped with nine rollers and an overall length of 1,025 mm, these tables facilitate the smooth transfer of goods in various industrial settings.

Key Features

- Enhanced Loading Efficiency: The integrated roller track allows for effortless movement of items onto and off the platform, reducing manual labor and increasing productivity.

- Robust Construction: Built to withstand rigorous industrial use, ensuring durability and longevity.

- Multiple Configurations: Available in both manual and electric operation models to suit different operational needs.

- Adjustable Heights: Scissor lift mechanism provides adjustable platform heights, accommodating various loading and unloading requirements.

- Safety Features: Designed with safety in mind, including secure locking mechanisms to prevent accidental lowering.

Specifications

| Model | Operation | Capacity (kg) | Closed Height (mm) | Raised Height (mm) | Platform Size (L x W mm) |

| LTSRT-BSL50 | Manual | 450 | 435 | 1000 | 1010 x 520 |

| LTSRT-BSL75 | Manual | 450 | 442 | 1000 | 1010 x 520 |

| LTSRT-BSL30D | Manual | 300 | 435 | 1620 | 1010 x 520 |

| LTSRT-BSL50D | Manual | 450 | 450 | 1500 | 1010 x 520 |

| LTSRT-ESL30D | Electric | 300 | 495 | 1600 | 1010 x 520 |

| LTSRT-ESL50D | Electric | 450 | 435 | 1618 | 1010 x 520 |

Applications

- Warehousing: Ideal for transferring goods between different areas, enhancing workflow efficiency.

- Manufacturing: Assists in moving components along the production line, reducing manual handling time.

- Distribution Centers: Facilitates the loading and unloading of packages, improving turnaround times.

- Logistics: Streamlines the movement of goods in and out of transport vehicles.

Related Products

- Turntable Roller Track Tables: Feature a rotating platform for versatile positioning during loading and unloading operations.

- Ball Transfer Top Tables: Equipped with ball transfer units for multidirectional movement of goods, ideal for assembly lines.

- Rough Terrain Mobile Scissor Lift Table: Designed for outdoor use, capable of navigating uneven surfaces while transporting materials.

Order Now

Enhance your material handling efficiency with our Straight Roller Track Tables. Order today and benefit from free delivery to UK mainland (excluding Highlands & Northern Ireland).

Frequently Asked Questions

General Product Information

1. What are Straight Roller Track Tables used for?

These mobile scissor lift tables are designed to assist in the smooth transfer of goods along a production or packaging line using integrated roller tracks on the platform.

2. What is the main advantage of a roller track platform?

The roller track enables effortless movement of boxes, containers, and goods onto and off the platform, improving workflow and reducing manual handling strain in repetitive tasks.

3. What is the typical lifting capacity?

Depending on the model, these tables generally support load capacities ranging from 300kg to 800kg, suitable for light to medium-duty material movement.

4. What is the maximum lift height?

Most models lift between 900mm and 1500mm, providing optimal working height for assembly, sorting, and production line integration.

5. Is the table constructed from durable materials?

Yes, it is manufactured from high-strength powder-coated steel with industrial-grade rollers fitted to the platform for long-term durability and efficiency.

Usage and Operation

6. How is the platform raised and lowered?

The platform is lifted via a foot-operated hydraulic pump, and lowering is controlled using a hand-operated release lever for smooth, gradual descent.

7. Are the roller tracks fixed or removable?

The roller tracks are fixed in position to maintain alignment with conveyor lines or transfer points, ensuring a consistent and efficient load flow.

8. Can the unit be repositioned easily?

Yes, the unit is mobile with four castor wheels—typically including brakes—allowing for easy repositioning and secure operation during use.

Maintenance and Care

9. What maintenance does the roller system require?

Regularly clean the rollers to prevent debris build-up and ensure smooth operation. Lubricate the moving parts of the hydraulic mechanism and check for any signs of wear.

10. Are spare rollers or hydraulic components available?

Yes, Liftruck UK can supply spare rollers, castors, hydraulic units, and associated parts. Contact us with your model number for assistance.

Purchasing and Delivery

11. What is the delivery timeframe?

Delivery is typically 2–3 business days, depending on your location, stock availability, and order quantity.

12. Can I order multiple tables for my production line?

Absolutely. Bulk orders are welcomed, and we can offer tailored pricing and support for larger operational setups. Contact us for a quotation.

13. How do I know if this table is right for my process?

Speak with our team about your production flow or packaging requirements. Call 0800 458 8025 or email info@liftruck.co.uk.

Safety and Regulations

14. Are these tables CE certified?

Yes, all our Straight Roller Track Tables are CE marked and comply with UK and EU safety standards for lifting and handling equipment.

15. Does this table require training to operate?

No specific training is necessary, but operators should read the manual, understand load capacities, and follow best practice lifting techniques during use.