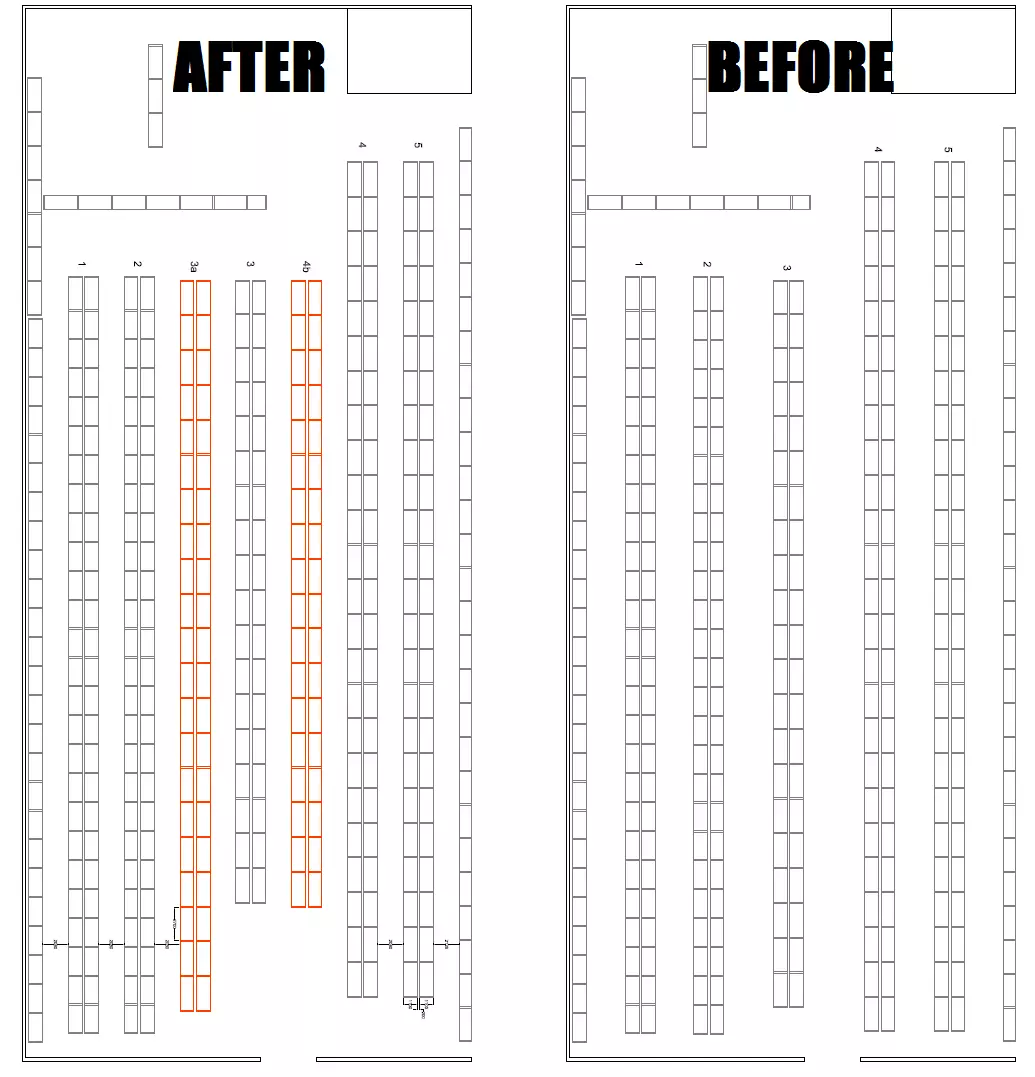

Warehouse Racking: Maximizing Storage Efficiency

Efficient warehouse racking systems are essential for optimising storage space, improving inventory management, and enhancing overall operational productivity. By selecting the appropriate racking solution, businesses can streamline workflows and adapt to changing inventory demands.

Types of Warehouse Racking Systems

- Selective Pallet Racking: The most common system, offering direct access to each pallet. Ideal for warehouses with a wide variety of products.

- Drive-In/Drive-Through Racking: Designed for high-density storage, allowing forklifts to enter the rack structure to store and retrieve pallets. Suitable for large quantities of similar items.

- Push-Back Racking: Utilises a system of carts on inclined rails, enabling multiple pallets to be stored on each level. Enhances storage density while maintaining selectivity.

- Pallet Flow Racking: Employs gravity rollers for a first-in, first-out (FIFO) inventory system, ideal for perishable goods.

- Cantilever Racking: Features arms extending from a central column, perfect for storing long or bulky items like timber or pipes.

Benefits of Implementing Effective Racking Systems

- Space Optimisation: Maximises vertical and horizontal space, reducing the warehouse footprint.

- Improved Inventory Management: Facilitates better organisation and quicker access to products.

- Enhanced Safety: Properly designed systems reduce the risk of accidents and product damage.

- Scalability: Modular designs allow for easy expansion as business needs grow.

Safety Considerations

Ensuring the safety of warehouse personnel and inventory is paramount. Key safety measures include:

- Regular Inspections: Conduct routine checks for signs of wear, damage, or misalignment.

- Load Capacity Compliance: Adhere to manufacturer-specified weight limits to prevent structural failures.

- Proper Training: Ensure staff are trained in safe loading and unloading practices.

- Use of Safety Accessories: Implement rack protectors, safety pins, and netting to enhance system integrity.

Contact Us

For expert advice on selecting the right racking system for your warehouse, please reach out to our team:

- Email: info@liftruck.co.uk

- Phone: 0800 458 8025